Graduation project. Assembly and welding of the tank

Content: 015_bak_dlya_syrnoy_massy.ZIP (580.68 KB)

Uploaded: 07.10.2016

Positive responses: 0

Negative responses: 0

Sold: 2

Refunds: 0

Seller: welder1

information about the seller and its items

Loyalty discount! If the total amount of your purchases from the seller more than:

| $10 | the discount is | 10% |

| $30 | the discount is | 20% |

$53.08

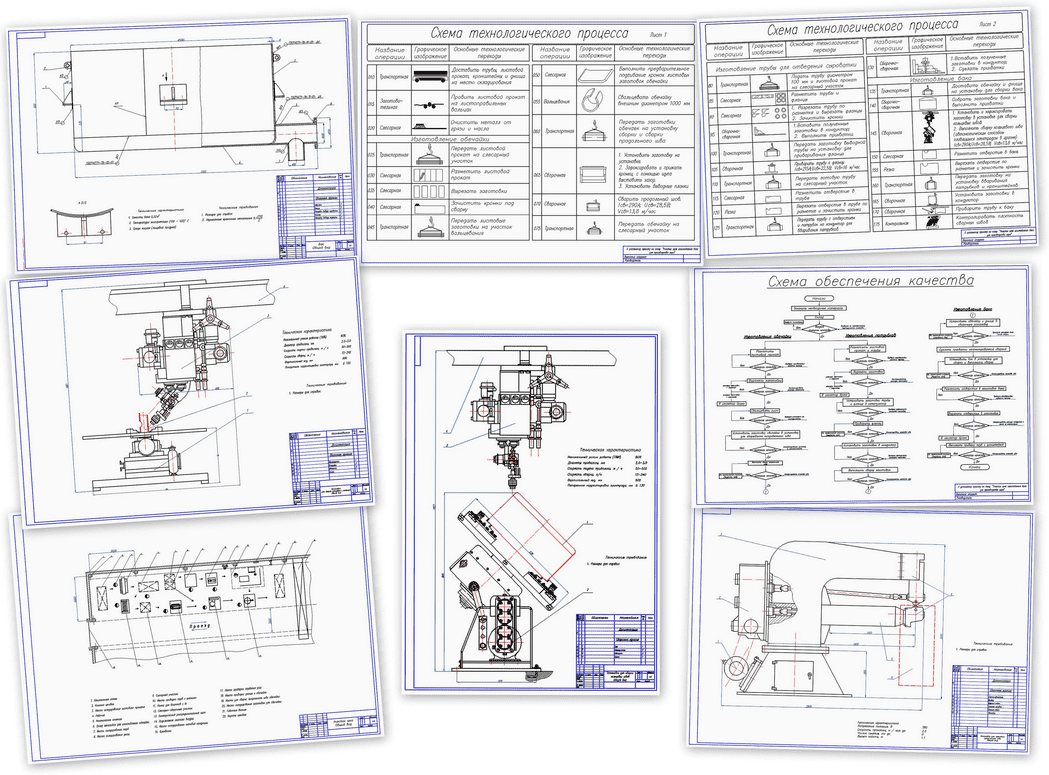

Graduate work. Assembling and welding for making cheese tank

Language of Work - Russian;

Sheets graphic part - 9 pieces;

ANNOTATION

It is proposed to introduce automatic welding consumable electrode Ar. Installation designed for welding the longitudinal seam shell, shell with welding head for welding a sleeve to the tube. Thus, a significant part of automated assembly processes and welding tank. In the economic section, calculate metrics for the new technology, as the number of workers, the wage fund, productivity indicators, capital investments and economic efficiency of the project resheniya.V section analyzes the main occupational health harmful production factors affecting the health of workers, and developed measures for their elimination.

Content

1 Panoramic ANALYSIS SECTION 6

1.1. Product description 6

1.2. Working conditions of the tank 7

1.3. Weldability 8

2 SECTION 12 OF TECHNOLOGY

2.1 Development process 12

2.2 The calculation of welding 14

2.3 The selection of welding consumables 15

Gas Selection 15

Selection of the welding wire 15

2.4 Selection of the type of welded joints, the size and edge preparation 16

2.5 Calculation of welding parameters on weld size 17

2.6 Welding Technology 22

2.7 Selection of welding equipment 23

Welding rectifier 23

The welding machine 23

3 DESIGN SECTION 24

3.1 units for the manufacture of the tank 24

4 CALCULATION OF ELEMENTS OF EQUIPMENT 30

4.1 Calculation pnevmoprizhimov 30

5 QUALITY CONTROL 31

6 DESIGN WORKSHOP AREA 32

7 ECONOMIC PART 33

7.1 The Organising Section 35

7.2 Economic section 41

8 HEALTH AND SAFETY 52

8.1 Analysis of the basic variant of the technology 53

8.2 Means and measures to improve working conditions 54

8.3 Personal Protective Equipment 63

8.4 Normalization of the environmental situation 63

8.5 Calculation of engineering solutions 64

CONCLUSIONS 66

REFERENCES 67

Applications 68

Language of Work - Russian;

Sheets graphic part - 9 pieces;

ANNOTATION

It is proposed to introduce automatic welding consumable electrode Ar. Installation designed for welding the longitudinal seam shell, shell with welding head for welding a sleeve to the tube. Thus, a significant part of automated assembly processes and welding tank. In the economic section, calculate metrics for the new technology, as the number of workers, the wage fund, productivity indicators, capital investments and economic efficiency of the project resheniya.V section analyzes the main occupational health harmful production factors affecting the health of workers, and developed measures for their elimination.

Content

1 Panoramic ANALYSIS SECTION 6

1.1. Product description 6

1.2. Working conditions of the tank 7

1.3. Weldability 8

2 SECTION 12 OF TECHNOLOGY

2.1 Development process 12

2.2 The calculation of welding 14

2.3 The selection of welding consumables 15

Gas Selection 15

Selection of the welding wire 15

2.4 Selection of the type of welded joints, the size and edge preparation 16

2.5 Calculation of welding parameters on weld size 17

2.6 Welding Technology 22

2.7 Selection of welding equipment 23

Welding rectifier 23

The welding machine 23

3 DESIGN SECTION 24

3.1 units for the manufacture of the tank 24

4 CALCULATION OF ELEMENTS OF EQUIPMENT 30

4.1 Calculation pnevmoprizhimov 30

5 QUALITY CONTROL 31

6 DESIGN WORKSHOP AREA 32

7 ECONOMIC PART 33

7.1 The Organising Section 35

7.2 Economic section 41

8 HEALTH AND SAFETY 52

8.1 Analysis of the basic variant of the technology 53

8.2 Means and measures to improve working conditions 54

8.3 Personal Protective Equipment 63

8.4 Normalization of the environmental situation 63

8.5 Calculation of engineering solutions 64

CONCLUSIONS 66

REFERENCES 67

Applications 68

Drawings made in AutoCad

No feedback yet